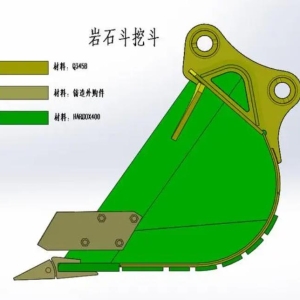

Excavator bucket, rock bucket manufacturer, also known as excavator bucket, is divided into anti-shovel bucket and positive bucket according to the working method. Generally, anti-shovel bucket is commonly used. According to the material bucket, it is also divided into standard buckets, reinforced buckets, rock buckets, gravel buckets, etc. The standard bucket material is made of 16Mn of domestic high-strength structural steel, which is suitable for the excavation of general clay and loose soil and the loading of sand, soil and gravel. The tooth seat plate and side edge plate material for the fragile part of the reinforcement bucket are made of domestic high-strength wear-resistant steel NM360, which is suitable for excavating hard soil mixed with soft rubble or gravel, gravel loading and other heavy-duty operations.

Preparation before excavator bucket operation:

1、The internal combustion engine part of the excavator needs to be operated in accordance with the relevant operating procedures.

2、Familiar with the relevant information of excavator bucket operation, understand the current construction environment, and make correct preparations.

3、When the excavator is in operation, it should check in advance the situation of the excavator at the site, including the solidness and stability of the soil, whether it is enough for the excavator to operate. Let the excavator operate safely and reliably.

4、Check the hydraulic system of the excavator bucket for oil leakage。

According to the function, the bucket is also divided into ditch bucket, cleaning bucket, tilt bucket, etc. The ditch bucket is suitable for the excavation of trenches of various shapes. Chaoyang rock bucket, trench excavation is formed at one time. Generally, there is no need for repair. The rock bucket is wholesale, and the operation efficiency is good. The grid bucket is suitable for the excavation of loose materials. The excavation and separation are completed at one time, and are widely used in municipal, agricultural, forestry, water conservancy and earthwork projects. The cleaning bucket and tilt bucket are suitable for the trimming of slopes and other planes, as well as the large-capacity dredging and cleaning of rivers and ditches. Among them, the tilt bucket can change the tilt angle of the cleaning bucket through the oil cylinder, which greatly improves work efficiency.

WhatsAPP

WhatsAPP